Rocket Storage Services: sustainable solutions for unneeded sets

Having started as a theatrical scenery storage business, the company has now launched Rocket Recycling and Repurposing, offering the industry a cost-effective and sustainable solution for its unneeded set materials – whatever they are made of

Rocket Storage Services in Nottingham houses more than 200 trailers of scenery, ranging from classics to recent hits, panto to opera and dance. Sets lie neatly dormant in their bays waiting on the call that sets them free to come alive again and to be what they were meant to be – theatre sets for live performance.

Rocket Storage Services was born out of Rocket Scenery 18 years ago. Now, Rocket Storage Services is introducing Rocket Recycling and Repurposing – a movement in the temporary and sometimes wasteful world of theatre. The aim of the company is simple yet bold: to completely reuse or recycle theatre scenery when it reaches the end of its productive life, so that nothing goes to landfill.

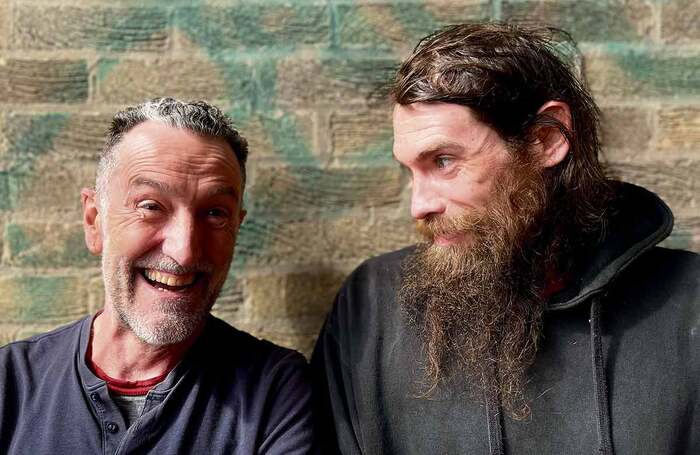

Andy Sharp, who co-founded Rocket, explains the journey: “When sets were no longer needed, we would put everything into recycle skips that were taken away. But as more theatre organisations started to be concerned about the environmental impact of waste, we were being asked where the skips were going, and what happened to the materials. I had no idea and so I’ve spent the past two years researching, calling up recycling companies and visiting treatment centres. It’s been a brilliant journey.”

Andy set about trying to find companies that would recycle these materials or find a use for them in a way that avoided landfill. He thought it would involve companies from across the UK, or even further afield. Instead, he found thriving reuse and recycling industries locally.

Andy says: “A year ago, we took a lease on a warehouse on our industrial estate and started taking scenery apart nail by nail and screw by screw. I worked in there by myself to begin with, buying and experimenting with different tools and equipment and developing techniques. The harsh reality of recycling scenery is that you have to take things back to component parts and then dispose of those materials separately.”

Continues...

The list of materials that scenery is built from is huge and growing more complex. Trailers of scenery for disposal often include costumes and props, built-in lighting and effects, and drapes. Everything needs to be recycled or repurposed.

Joe Tutty manages the day-to-day running of Rocket Storage Services and has been instrumental in building relationships with theatres and other organisations. “We’ve made a lot of contacts with people who are interested in specific items,” Joe explains. “You just need to find the right people for the right products. We hate to throw things in recycling that could have a second life, but as more and more scenery comes in for processing, it is the floor space that we need. Things have to turn over quickly.”

The first priority for Rocket Recycling and Repurposing is to have materials reused. As Andy explains: “Steel, aluminium and copper are straightforward to recycle. They get smelted and made back into steel, aluminium and copper. Timber is far more complicated. Good condition plywood is a great material to put back into the industry as it helps companies comply with the Theatre Green Book initiative. Other timber is harder as it often has fabrics, plastics or paint applied. This timber is packed and sent to a biomass boiler just outside Nottingham where it helps to generate electricity for 12,000 homes in south Nottingham. A year ago, I didn’t know the place existed.”

Meanwhile, fabrics and plastics are sent to a state-of-the-art facility less than 40 miles from Nottingham.

“Joe and I spent a fascinating morning being shown around the facility,” continues Andy. “Everything is put into a hopper where it is shredded into pieces around 30mm by 30mm. These go on to a conveyor belt that moves at tremendous speed and travels under a ‘magic eye’ where the material is read and identified. As the material reaches the end of the conveyor, thousands of directional air jets blow the pieces on to more conveyor belts for the system to further refine the pieces. That’s how they sort out recyclable plastic from non-recyclable plastic. Anything that doesn’t get recycled there becomes Refuse Derived Fuel, which is then sent on to biomass boilers. Again, a year ago I didn’t know any of this. It is reassuring to know that there are industries out there that support what we are trying to do.”

In the recycling space, a huge steam engine waits to be disassembled. Although it looks like a gleaming chunk of metal from the Victorian era, “it’s mostly wood”, Andy explains. He turns it around and finds the bolts inside. “That’s where we’d start, unscrewing all of those, taking the electrics out – we give lots of second-hand electrics away to smaller theatre groups, too – and then we break the wood down.”

Continues...

As much as he has relished this new approach, it’s not been without its challenges. The first show Rocket Recycling and Repurposing tackled was made almost entirely of fibreglass.

“We hadn’t even thought about fibreglass, and we very quickly had to find a way to recycle it,” Andy admits, “but it was a learning experience.”

By charging a flat fee per trailer, almost the same as the cost to send to landfill, Andy is ensuring that reuse and recycling isn’t only the right thing to do, but it’s cost effective for clients, too.

And the response from the theatre community has been overwhelmingly positive. “Sustainability is such an important thing in theatre now. It’s the right direction for the industry and the planet,” Andy notes.

“As a manufacturer, you’re asked to sort your materials in a certain way and demonstrate that a percentage of it is made from recycled materials. But what happens at the end of its life? That’s where we come in.”

Most Read

Across The Stage this weekYour subscription helps ensure our journalism can continue

Invest in The Stage today with a subscription starting at just £7.99